Even in the 21st century, concrete remains an extremely topical, versatile and reliable material.

In the countless applications that see it as a protagonist every day, concrete provides the expected performance. Sometimes, however, from a structural, aesthetic and functional point of view, drawbacks can occur, often attributable to the quality of its components, their incorrect proportioning, the mixing method on the construction site or in the concrete batching plant, the environmental conditions during mixing and setting in place, the construction procedures used and so on. In these cases, it is necessary to identify the most suitable and convenient repair intervention, by promptly identifying the cause or causes that led to the event.

The following notes are sufficiently detailed in proposing some simple notes to guide, “as a first approximation”, the identification of the forms of degradation, the origin of the deterioration in progress, the preventive measures and the possible remediation methods.

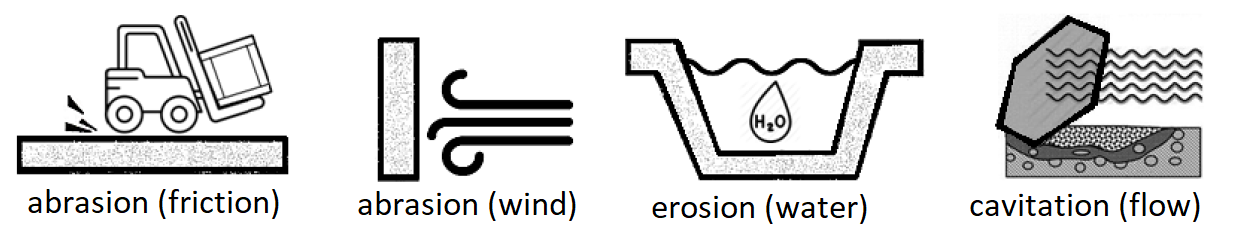

DESCRIPTION: The term abrasion defines both the stress and the degradation of a surface subjected to friction. Erosion can be considered a form of abrasion of a surface, while cavitation occurs when a stress occurs with non-linear flow, with speeds above 12 meters/second.

As an example, concrete floors, which unequivocally represent the wear and tear of surfaces due to attrition, are subject to friction abrasion; in hydraulic structures, the action of water and the transported abrasive materials (sand and stones) leads to erosion processes.

When hydraulic works are subjected to swirling bubbles, capable of generating nonlinear flows, the stress that derives from this is cavitation.

ORIGIN OF THE PROBLEM: The defect/damage, attributable to the service conditions is made possible and/or amplified, by the possible inadequate quality of the concrete as well as by any stresses of an entity not contemplated in the project.

POSSIBLE CONSEQUENCES: Slow or rapid decay of the functional and performance quality of the structure concerned.

PREVENTION MEASURES: Adaptation of the mix-design of the concrete and of the performance characteristics of the components to the foreseeable abrasion and/or erosion stresses (a). Possible preparation of hardening systems for exposed surfaces (b).

(a) = specifically designed concrete with high intrinsic cohesion and reduced water/cement ratio, added with silica fume ( MICROSIL 90 ), where possible and necessary, fiber-reinforced with synthetic and/or steel fibers ( READYMESH )

(b) = construction of extrados hardening systems

RECLAMATION METHODS: Significant degradation conditions necessitate cortical restoration (reconstruction), after removal of the conglomerate which is in any case affected by the degenerative processes ( FLOOR Q and FLOOR TENAX ). Initial degradation conditions can be remedied by cleaning the surfaces and applying hardeners, of the non-film impregnating type, such as QL NANO LITHIUM HARD and QL FLUOSIL.

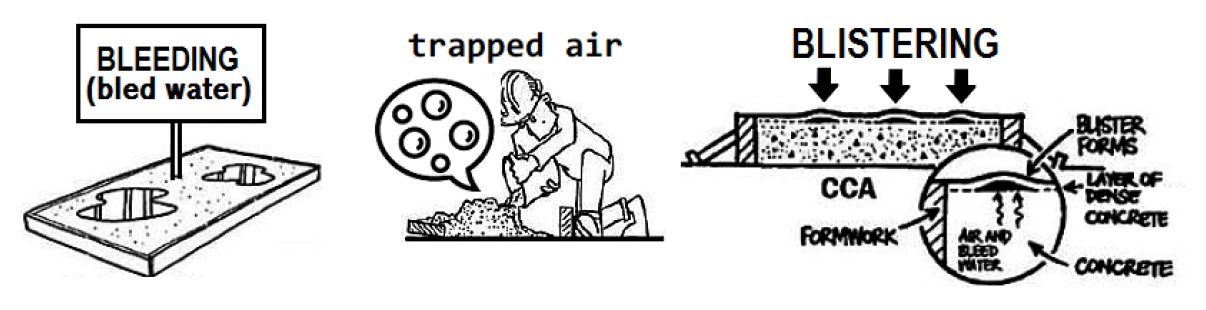

DESCRIPTION: The appearance of bubbles on the surface of fresh concrete or in the first hardening phase is generally identified with the term “bugholes”. The bubbles can vary in size from a few millimeters to tens of millimeters. Sometimes they can reach even larger sizes. They are coated with a film of dense mortar and may initially contain both accidentally entrapped air and concentrations of surfacing water. While the larger bubbles are easily identified and allow some form of intervention, those of a smaller size, especially in low light conditions, can go unnoticed. In any case, if neglected, the blistering bubbles will manifest themselves with fractures and disruptions, as soon as the surface is subjected to traffic.

ORIGIN OF THE PROBLEM: The defect/damage, often attributable to errors in the mix design and mixing of the concrete (grain size, cement content, excessive water-cement ratio, etc.), can derive or accentuate even in the presence of oversights in the execution such as accidental incorporation of air, untimely smoothing, etc.

POSSIBLE CONSEQUENCES: With the hardening of the concrete, the bubbles represent critical elements of fragility. Subjected to stresses (traffic), they quickly fracture causing aesthetic/functional discontinuities, dust generation, as well as locations of further rapid degradation.

PREVENTION MEASURES: Adjustment of the mix-design and the performance characteristics of the components, adjustment of the processing methods and times: installation, application of hardeners ( FLOOR VULKAN ), smoothing, etc … The crushing of the bubbles in phase plastic can be considered a generic remedy which, however, if carefully and promptly put in place, can significantly reduce the consequences mentioned above.

RECLAMATION METHODS: With the occurrence of bubble fracturing and consequent degradation, the possible remediation methods contemplate cortical restoration (reconstruction), after removing the conglomerate which is in any case affected by the degenerative processes (for example FLOOR Q or FLOOR TENAX ) .

The chromatic and texture homogeneity of the surfaces can be restored with the application of non-film, pigmented hardening solutions (of the type QL NANO LITHIUM COLOR ), which can also confer significant anti-abrasive protection.

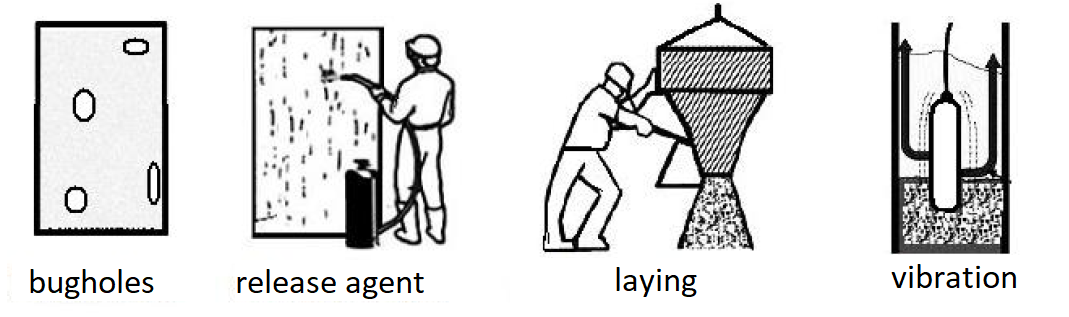

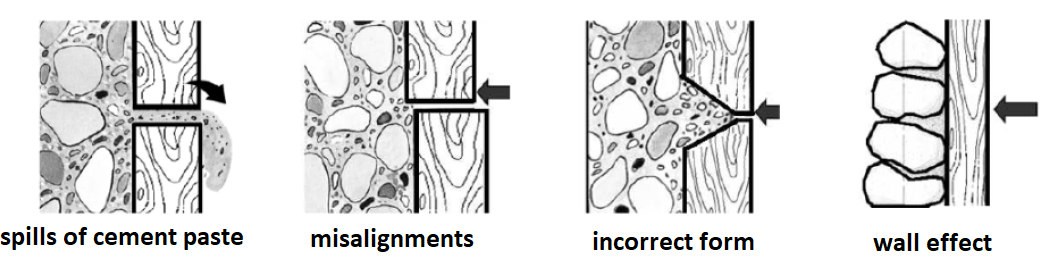

DESCRIPTION: They represent the consequence of the formation, caused by various incorrect execution, of voids (bubbles), of variable size and quantity, close to the continuous surfaces, generally the formworks. The discovery of these bubbles is generally a surprise that occurs upon formworks removal.

ORIGIN OF THE PROBLEM: Migration, in adjacency to the internal surfaces of the formworks, of air and water driven by the heat of the fresh concrete and/or by the actions connected with the compaction (vibration etc.). It can also derive from imbalances in the grain size distribution, from the inadequate quality of the release agents, as well as from the solubilization of the cellulose and hemicellulose of the wooden formworks.

POSSIBLE CONSEQUENCES: The problems deriving from the presence of “bugholes” are above all of an aesthetic type even if, sometimes, they can affect the durability of the work. The actual structural aspects are not involved.

PREVENTION MEASURES: Adaptation of the mix-design, in terms of particle size and cohesion of the matrix, adjustment of the times and methods of installation and compaction (vibration), use of suitable formwork and chemical release agents, non-oily.

RECLAMATION METHODS: Filling the bubbles, after careful preparation, with the use of cement mixes with a maximum diameter proportionate to the size of the bubbles, added with binders and polymeric adhesion promoters suitable for the color of the adjacent surfaces (for example of the BOND HG type, for dark surfaces and BOND IDRO, for tendentially lighter surfaces). In general, it is advisable to carry out some preliminary tests to identify the mixtures with colors, after hardening, more homogeneous than the adjacent conglomerate.

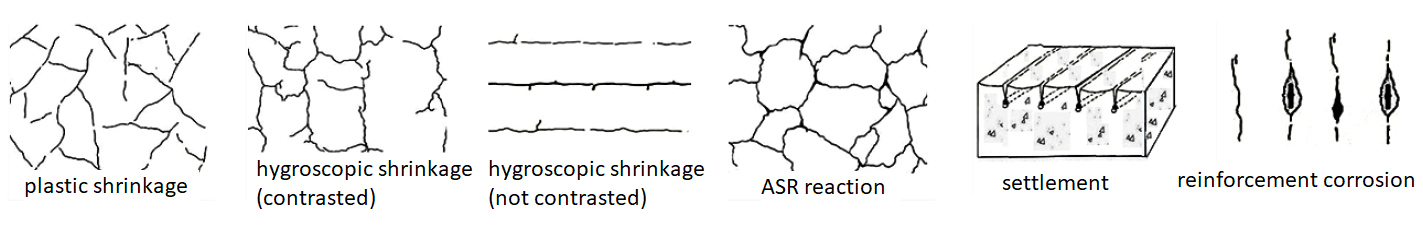

DESCRIPTION: The concept of “cracking” implies the phenomenon of the generation of cracks in concrete structures.

With the appearance of cracks in the concrete surface, the external environment can more easily come into contact with the reinforcement. For this reason, the Building Technical Standards establish a maximum width of the cracks found on a concrete and impose a verification of the limit state of cracking. According to the NTC, the maximum width of the slots must respect the following values: w1 = 0.2 mm; w2 = 0.3 mm; w3 = 0.4 mm identified on the basis of environmental conditions: very aggressive (w1), aggressive (w2), ordinary (w3). As example, the further schematic representations for the identification of the causes of cracking proposed in the document ACI (American Concrete Institute) 224.1R-07 are reported.

ORIGIN OF THE PROBLEM: Concrete is subject to contractions and expansions, with the variation of the moisture content and temperature. Further variations can be induced by the load conditions, by those of the support and so on. If these movements are not adequately foreseen, in the project context or in the construction methods, damages (cracks) of various nature and appearance may occur. Some of these lesions are summarized below. The origin of the cracks is generally classified through two fundamental categories: the area preceding the hardening of the concrete (often designated as PRE-HARDENING) and the subsequent context (POST-HARDENING).

- The first categoryincludes: the cracks induced by ACCIDENTAL MOVEMENTS of the conglomerate, the formwork and the substrate, the cracks induced in the plastic phase by the PLASTIC RETREAT, by the PLASTIC SETTINGS, as well as the cracks induced by seasonal causes, for example those caused by CONCRETE FREEZING.

- Belonging to the second category: the cracks induced by PHYSICAL CAUSES, such as the hygrometric shrinkage, the crazing and the contraction of the aggregates, the cracks induced by STRUCTURAL CAUSES, such as design loads, creep and accidental overloads, by THERMAL CAUSES, such as thermal contractions, the incidence of external constraints and internal thermal gradients, as well as the cracks induced by CHEMICAL (or electrochemical) CAUSES, such as carbonation, the aggregate alkali reaction and corrosion of the reinforcements.

POSSIBLE CONSEQUENCES: In general, the presence of “crack”, indicates something that breaks. Undoubtedly, apart from the aesthetic aspects that do not benefit from it, the risks of decay of durability are to be carefully evaluated. Just as the possible effects on structural integrity must be considered, albeit rather infrequently. In current practice, the slits of reduced opening, less than 0.3 mm, not affecting the entire thickness, are generally neglected from a structural point of view.

PREVENTION MEASURES: Given that it is practically impossible to obtain a concrete completely free from cracking phenomena, the cracks can be reduced and controlled through procedures that involve the mix design of the concrete, the correct sizing of the concrete cover, the finishing and curing methods, the careful preparation of the joints, where necessary. A concrete consistent with current regulations (UNI EN 206-1), cohesive, where possible and/or necessary fiber-reinforced (for example with READYMESH polypropylene fibers), represents the first anti-cracking prevention measure.

The quality of the concrete mentioned above must be combined with the prior definition and preparation of the joints and with the safe determination of concrete cover thicknesses such as to avoid the onset of corrosion processes. As regards the casting, compaction, finishing and wet curing procedures, provided that finishing operations must not be carried out in the presence of surfacing water (bleeding), the care and wet curing must be continued, continuously, for 7 days, with specific protections against thermic events, direct sunlight and exposure to the wind. In the case of horizontal slabs (concrete floors), the adequate preparation of the substrates is also of fundamental importance.

RECLAMATION METHODS: The remediation of cracking manifestations requires prior identification of the same in terms of size (opening) and relative thickness, with respect to the thickness of the product (relative height). In the absence of structural reliefs, the reclamation must provide for the convenient opening of the crack including the removal of the degraded conglomerate and the dust, the sealing or topping to be carried out with a material suitable for the filling sections and the subsequent protection of the surfaces. As an example, the sealing of millimeter cracks can be carried out with extrudable and/or spatulable polymeric systems (EG91 , PROTECH FLEX or PROTECH SIGILFLEX MONO), with pourable cement systems (such as GROUT CABLE or GROUT MICROJ). The filling, in the dimensional range 5/12 mm can be carried out with cement mortars (type REPAR SM or REPAR TIX), the filling of widths greater than 12 mm can be carried out with pourable cement mortars (type GROUT 2 or GROUT 6) or thixotropic (REPAR TIX). Also very interesting is the sealing with the special epoxy resin SYNTECH ROADWARE to be poured into the cracks after opening them with a flexible disk. For consolidating protection, systems applied by brush or spray can be used (such as QL FLUOSIL or QL NANO LITHIUM HARD).

DESCRIPTION: The term “crazing” can be translated as the appearance of widespread cracking, with random distribution, generally thin and shallow (= <mm 3). The chaps described describe hexagonal areas between 30 – 40 millimeters in size. More rarely they can define areas between 8 and 12 millimeters. The moment of “formation” of the cracks is generally attributable, also in terms of cause, to the plastic phase, of first hardening. The “visibility” of the cracks, sometimes not immediate, becomes noticeable when the concrete surface is wet.

ORIGIN OF THE PROBLEM: The formation of the cracks is almost always associated with the non-observance of rules inherent in the technology of concrete. Among these defaults we mention the excessive water/cement ratio, the insufficient cohesion of the mixture and the consequent surfacing of water (bleeding), the application of hardening dust in the presence of surface water, the protracted or untimely finishing trowels, the incorrect and discontinuous curing procedures (intermittent wetting), the lack of “curing” in the presence of wind or direct solar radiation, etc. In some cases, however quite rare, the phenomenon can be traced back to the exasperation of carbonation processes.

POSSIBLE CONSEQUENCES: In principle, the crazing cracks have only aesthetic value even if the superficially cracked concretes, exposed to the weather, can also undergo significant reductions in durability.

PREVENTION MEASURES: To avoid the occurrence of cracks, particularly frequent in “spatulated” surfaces, it is necessary to avoid mixes with excess water on the surface, using suitable additives (for example FLUID S), increasing the cohesion of the mixture (for example with MICROSIL 90), protect the surfaces from the wind and direct sunlight, do not carry out finishing in the presence of water emerging (bleeding), do not extend the trowelling time, do not use ventilation drying methods, avoid intermittent curing cycles ensuring a convenient continuous wet curing of exposed surfaces.

RECLAMATION METHODS: The objective of remediation, generally represented by the reduction of aesthetic decays and the safety of surfaces, especially if external and exposed, against atmospheric events, is easily achievable through the application of a protective hardener, non-film, nano-technological ( QL NANO LITHIUM ), capable of drastically limiting the absorption of water, at the origin of showy imperfections, while ensuring, at the same time, the best protection of the surfaces.

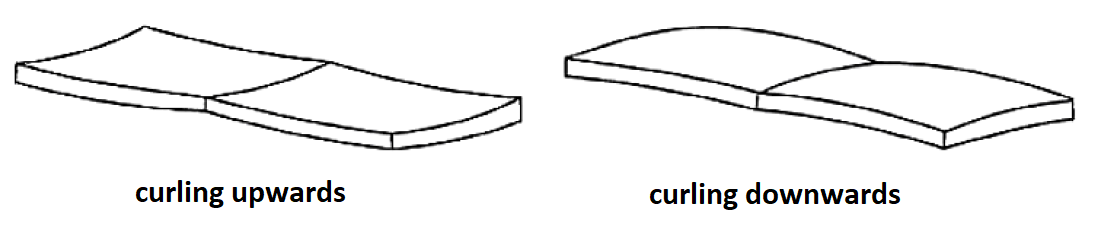

DESCRIPTION: The embedding (distortion in an upward or downward curved form) of concrete slabs is commonly defined as “curling”. Curling, which can occur more or less early, causes the edges to be raised, often at the corners.

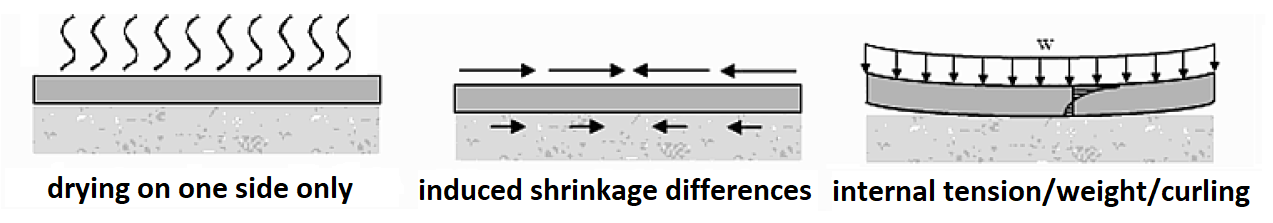

ORIGIN OF THE PROBLEM: Generally the cause of the raising and/or arching at the edges of a concrete slab is due to contractions of the upper part of the slab, compared to the underlying part, determined by differences in humidity and/or temperature. In particular, the transfer of concentrated moisture to the extrados involves important differences in the extent of the hygroscopic shrinkage with consequent internal tensions capable of generating deformation.

The most frequent causes are attributable to the non-contrasted shrinkage of the concrete, bleeding, the differential tensions induced by the hardening dust, direct solar radiation, grazing ventilation, significant differences in ambient temperature and between the extrados and the lower surface of the concrete slab, as well as the inadequate distance adopted between the contraction joints.

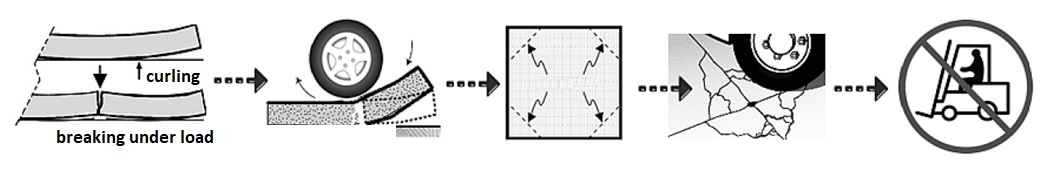

POSSIBLE CONSEQUENCES: The occurrence of curling is mainly associated with concrete slabs such as concrete bases and floors. In the latter structures, clearly of an operational nature, the occurrence of the phenomena mentioned often results in the rapid appearance of damages, generally at the corners of the slab, as a consequence of the lifting and fractures under load. The final result can be represented by the concrete unusability of the flooring.

PREVENTION MEASURES: They consist of the adoption of measures aimed at drastically reducing the effects of the main risk factors: hygroscopic shrinkage, bleeding, direct solar radiation (curling downwards), rigid ambient temperature, in the plastic phase and first hardening (curling upwards), grazing ventilation, excessive spacing between the contraction joints. Consequently, the adoption of low-shrinkage and/or controlled shrinkage concrete mixtures as essential prevention measures. In any case, the conglomerates must be characterized by reduced values of the water-cement ratio and by a high intrinsic cohesion (for example with MICROSIL 90 + FLUID S + READYMESH PM-180). The absolute inhibition of the additions of water during the work, the rigorous attention to the curing procedures and prolonged wet curing, the predisposition of contraction joints suitably spaced according to the thickness of the mix, the critical evaluation of the adoption or not of barriers against rising damp, evaluation, equally critical in terms of the opportunity to use hardening systems by dusting and/or pastes, implemented with the “fresh on fresh” method.

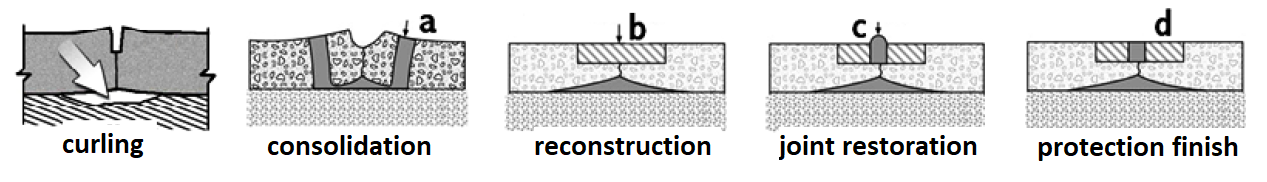

RECLAMATION METHODS: The most used methods to restore the usability of the concrete slab (flooring) on the extrados contemplate the consolidation of the continuity of support to the substrate, the reconstruction of planar continuity, preceded by the removal of the degraded concrete, functional restoration joints and protective finish. The consolidation on the support is generally achieved by practicing perforations and injecting pourable mortars or grouts, moderately expansive (such as GROUT MICROJ or GROUT CABLE). For the reconstruction of planar continuity, preceded by the removal of the degraded conglomerate by suitable milling, pourable structural cement mortars are used (GROUT 2 o GROUT 6, depending on the filling dimensions). The functional restoration of the joints requires adequate sealants in terms of deformability and Shore hardness. The protective finish requires products capable of ensuring the required performance, in terms of abrasion resistance and waterproofing, protective capacity (QL NANO LITHIUM).

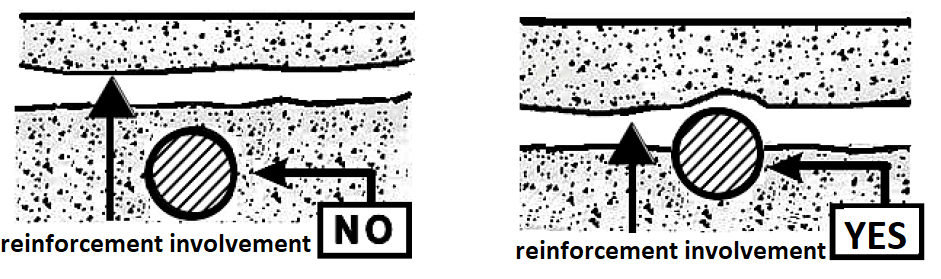

DESCRIPTION: It can be defined as a separation (splitting) of a concrete layer according to a plane parallel to the surface. Rather evident in cases of advanced deterioration it is however found with simple percussion or dragging systems and, for more in-depth investigations, with specific detection instruments. The involvement or otherwise of the reinforcement represents a discriminating element to qualify the delamination processes. If the reinforcement is involved, the implications are structural and the remediation procedures must also be considered as real structural restoration. If the reinforcement is not involved, the remediation procedures may be limited to functional and/or aesthetic aspects.

ORIGINS OF THE PROBLEM: The genesis of the most common delamination processes can be identified in the inadequate installation and consolidation procedures (segregation and cold joints), in the outcrop water (bleeding) trapped, in incorrect surface repairs, in inadequate quality and size of the concrete cover, in the penetration of water in freezing/thawing conditions and in the expansion by corrosion of the steel reinforcement. In the context of inadequate repairs, as possible causes of delamination, dimensional variations, contractions and/or expansions, which may occur between the material used for the existing concrete, must also be carefully considered.

POSSIBLE CONSEQUENCES: In the absence of structural implications, the consequences of delamination can still represent an element capable of affecting the structural integrity over time and, in the case of concrete flooring, the usability of the works. The possible consequences in terms of durability are always to be carefully evaluated.

PREVENTION MEASURES: The measures that can counteract the onset of delaminations include the construction arrangements capable of ensuring the correct thickness of the concrete cover, the design of cohesive and bleeding-free concrete mixtures, the adoption of sizing and laying methods for the concrete such as to avoid the formation of improper joints, the timeliness of the finishing works consistent with the quality of the conglomerate and with the environmental conditions, together with the necessary measures of care and curing.

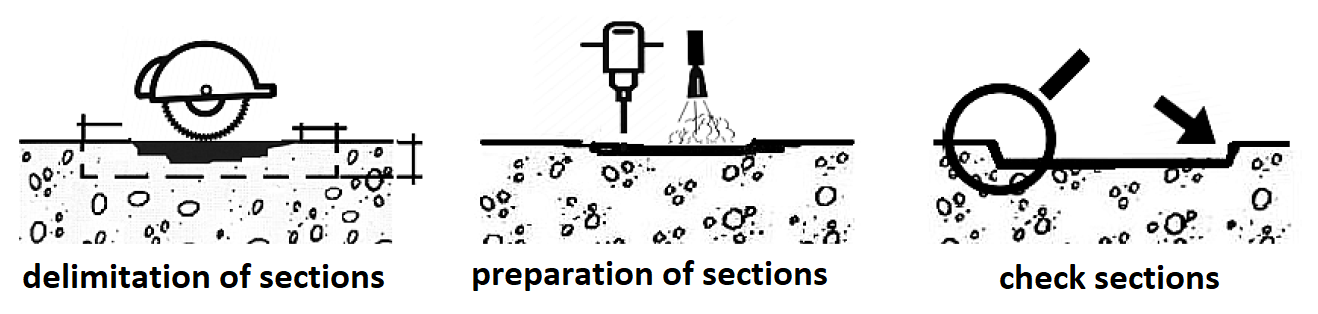

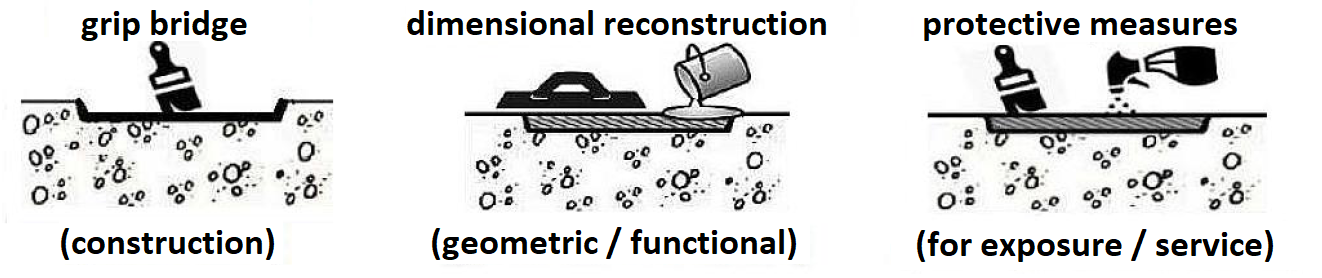

RECLAMATION METHODS: The most relevant aspects in the delamination remediation interventions can be condensed in the succession of preliminary operating phases including the identification (direct and/or instrumental) of the areas actually compromised, the delimitation of the intervention areas, including the preparation of the same by means of perimeter cuts (of a depth of not less than 6 mm), the removal of degraded or in any case compromised concrete and the accurate dust removal of the resulting surfaces.

In accordance with what has already been mentioned, delaminations that significantly involve the reinforcement must be considered and dealt with as structural repairs.

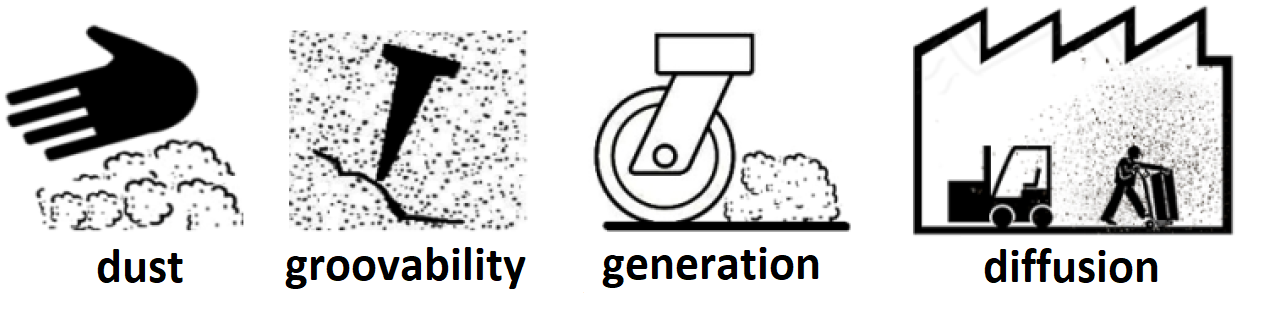

DESCRIPTION: In general, the term “dusting concrete surface” defines chalking and/or the formation of dust on concrete surfaces. A characteristic easily found in surfaces subject to “dusting” is represented by the easy “rigidity to the nail”.

ORIGINS OF THE PROBLEM: The formation of dust (“dusting”) in the concrete surfaces subjected to friction is certainly consequent to the “weakness” of the concrete as such or to the weakness that occurred due to different causes, often coagent. For concrete as a whole, the water/cement ratio, the possible criticalities of the hydration processes (setting and hardening of the binder), as well as those occurred due to improper exposure to climatic events: wind, sun, rain, temperature, etc.

An important critical factor is also attributable to the outcrop of free bleeding water, both due to insufficient cohesion of the mixtures and the presence of non-absorbent substrates or horizontal waterproofing devices (vapor barriers), capable of increasing the outcrop of free water. Untimely processing, carried out in the presence of bleeding, can also provide the decisive contribution for the “generation” of the dust.

POSSIBLE CONSEQUENCES: The tendency for the generation of dust on concrete surfaces can lead, more or less rapidly, to the wear and tear of the surfaces themselves up to the occurrence of “operational criticality” in industrial flooring. The presence of dust in the workplace can also lead to unhealthy problems connected with the inhalation of dispersed particles of silicon dioxide (silicosis).

PREVENTION MEASURES: Use carefully designed concrete mixtures; cohesive, with a water/cement ratio of max. 0.50 in concrete pavements in contact with the ground, always evaluate the provision of barriers against rising damp; Do not carry out finishing operations in the presence of surfacing water; Take care of the protection and wet curing of fresh concrete surfaces, however exposed.

RECLAMATION METHODS: They are essentially represented by the application, after careful preparation and de-dusting, of specific impregnating, non-pellicular chemical hardeners, both nano-technological based on lithium silicates ( QL NANO LITHIUM ) and based on fluosilicates ( QL FLUOSIL ).

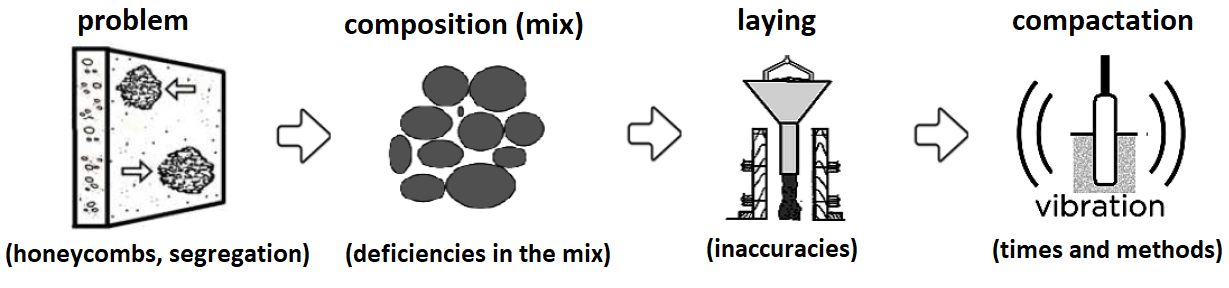

DESCRIPTION: the term “honeycomb” are defined as volumes of macro-voids that form on the surface or inside the concrete, following segregative locations of aggregates that are not adequately covered and connected by the cement paste .

ORIGINS OF THE PROBLEM: The set of causes that contribute to the formation of “honeycombs” is generally attributable to inadequacies in the quality control of concrete: planning, mix design, mixing, transport and installation. The shortcomings regarding the quantity of cement paste and the correct “fine” content represent the “trigger” element of the segregative processes, processes that can acquire further relevance in the presence of errors in the installation and in the compacting operations of the conglomerate.

Even any inaccuracies in the construction of the containment formwork can increase the incidence of segregative phenomena and the quantitative and dimensional entity of the “honeycombs”.

POSSIBLE CONSEQUENCES: The “showy” segregative manifestations represented by the “honeycombs” mainly affect the appearance of the structures. In the most pronounced cases, the functional and service aspects can be affected. In any case, they are prejudicial to the durability of the works.

PREVENTION MEASURES: They can be summarized with interventions on the mix design, as well as on the laying and compacting methods. As regards the mix design, interventions aimed at increasing the cement paste content and the cohesion of the mix through the design of mixtures, which are in any case consistent with granulometric compositions of a continuous type, with a higher content of cement and fine aggregates, are certainly recommended.

The addition of silica fume-based fillers (MICROSIL 90) can also provide important contributions in terms of the quality and quantity of binding paste. The addition of polypropylene fibers (READYMESH) allows significant increases in the cohesion of the mixes when fresh.

RECLAMATION METHODS: The possible remediation methods, aimed at remedying the aesthetic consequences and protective deficiencies, contemplate the cortical restoration (filling), after adequate preparation, with thixotropic cementitious mortars, trowelable, adhesive, with compensated shrinkage, (for example REPAR SM , REPAR TIX or REPAR TIX HG). The color and texture homogeneity and the restoration of the necessary protective performance can be pursued through the application of specific paints (such as PROTECH WAC and PROTECH WAC-T).

DESCRIPTION: The alkali-silica or aggregate alkali reaction (ASR) can be, at the same time, a “defect” and a cause of almost always congenital degradation, deriving from the presence of amorphous silica in the large granules of the aggregate. It represents a significant problem in some countries. In Italy it occurred more sporadically and in defined geographical areas, especially in the provinces of Ravenna, Pesaro Urbino, Ancona, Pescara, Campobasso and Foggia.

It manifests itself in various ways: on concrete pavements, it generally occurs punctually, with inverted truncated-conical detachments, of limited size, which expand, to form flakes with more or less important detachments, often accompanied by the presence of gelatinous drops (alkali-rich silicon gel). In the structures it determines the appearance of diffuse cracks, destined to deteriorate further over time.

ORIGINS OF THE PROBLEM: The reaction occurs when the necessary preconditions occur: a concrete with a high alkali content in the cement, the simultaneous presence of reactive aggregates and the existence of relative humidity values higher than 85%, and is often highlighted by the appearance of “gel” around the aggregates. Opal, chalcedony, tridymite, and cristobalite are the most common forms of aggregates containing reactive silica. In reality the origin of the alkalis can also be external, for example when the concrete comes into contact with the sodium chloride solutions, deriving from the de-icing salts used in the road system.

POSSIBLE CONSEQUENCES: The damage occurs both in the form of a widespread network of cracks (called “geographical map”) on squat elements, such as plinths, both as linear cracks parallel to the long side of the artefacts on elongated elements (pillars), and finally as “inverted cones” which detach themselves mainly from the surface of floors, called “pop-outs”. In practical terms, the consequences of the ASR can assume the functional values which, in concrete pavements, also include the impossibility of a correct use of the work, while in structures and in the most extreme cases, static aspects can be affected, performance and durability.

PREVENTION MEASURES: The expansive process of the alkali-aggregate reaction can be controlled, up to the practical inhibition, through the addition, during the concrete mixing phase, of fillers capable of “engaging” the alkalis, subtracting them from the reaction itself. Among the different options, the superpozzolanic silica fume (microsilica) fillers, of the MICROSIL 90, represent the most cited solution in the literature for their proven effectiveness in decades of experimentation and practical applications, also certified in the extensive literature available on the subject.

RECLAMATION METHODS: The possibilities of intervention on existing concrete structures and floors, affected by the reaction of aggregate alkalis have always been scarcely reliable, sometimes even harmful in their effects. Coatings with various types of synthetic resins, for example, have often accentuated and/or accelerated the phenomenon. The most up-to-date advances in the nano-technology of lithium compounds have made available solutions that are proving to be decidedly promising. Among the solutions mentioned, QL NANO LITHIUM, is particularly interesting for the peculiar characteristic of “non-film impregnating agent”, easy to use, reliable in functional terms, free from the risks of accentuation and/or acceleration of the reaction.

DESCRIPTION: ACI document 201.1R: “Guide for carrying out visual inspections of concrete in service” defines the phenomenon as “localized flaking” of superficial portions of concrete (or of concrete conglomerates in general), of an entity varying from particles reduced to flakes of significant dimensions, greater than 20 millimeters, often accompanied by the exposure of the largest aggregates.

ORIGINS OF THE PROBLEM: A series of often coagent causes can be listed such as: mix design inadequate to the exposure conditions (exposure class), due to lack or incorrectness of the air included, excessive water-cement ratio, processes carried out in the presence of bleeding, effects of freeze/thaw cycles, inadequate curing, aggressive action of antifreeze melting salts, applications of hardening dust on cementitious flooring with inadequate characteristics.

POSSIBLE CONSEQUENCES: The surface discontinuities and the exposure of the internal layers of the conglomerate, consequent to scaling, can determine aesthetic, functional criticalities and, triggering further degenerative processes, of durability of the works. The extent of the consequences mentioned is related to the significance and distribution of the events.

PREVENTION MEASURES: The design of mix designs suitable for the exposure class, in terms of water/cement ratio, air content, etc., together with the correct laying and curing methods, represent the most recommended prevention measures. The addition of polypropylene fibers like READYMESH provides additional safeguards.

RECLAMATION METHODS: They are essentially represented by the reconstruction of the areas concerned with cement mortars suitable for the exposure conditions, after careful preparation and dust removal of the substrates. For the restoration and/or increase of the protection conditions it is possible to resort to the application of specific impregnating, non-pellicular, nano-technological, lithium silicate-based protectors (QL NANO LITHIUM).

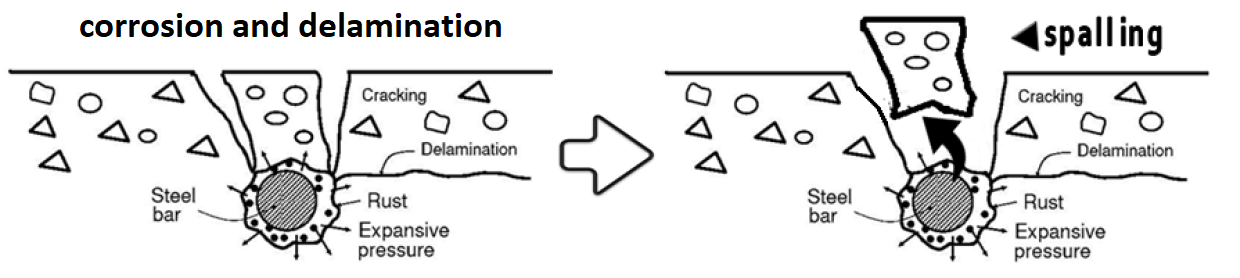

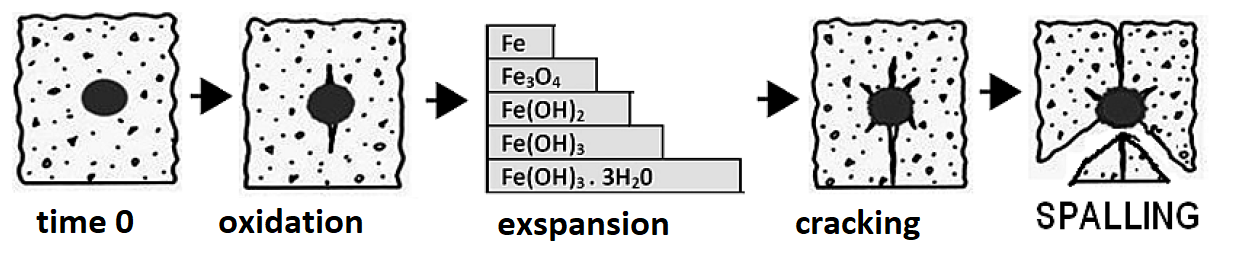

DESCRIPTION: The phenomenon called spalling is a consequence of corrosive, oxidative and expansive processes that can occur in structures in reinforced concrete. It is evidenced by the destruction and the expulsion, more or less deep, of the layer of concrete placed to protect the reinforcement.

ORIGINS OF THE PROBLEM: The “depassivation” of the concrete/steel interface and the consequent loss of protection of the steel, which is thus exposed to oxidative and corrosive processes, is the most general cause of spalling phenomena.

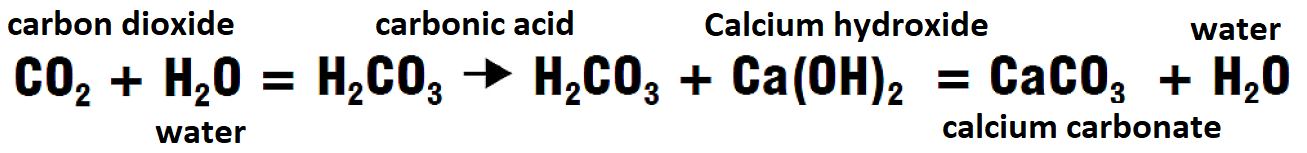

The “depassivation” of the concrete/steel interface is generally consequent to the carbonation processes of the concrete, through the reaction:

The reaction product, calcium carbonate, has an insufficient pH to maintain the protection condition by passivation of the steel that constitutes the reinforcements. The oxidative, corrosive and expansive phenomena mentioned follow. In order to better understand the importance of water, such as humidity, it is appropriate to consider that carbonation is not the reaction of a gas, carbon dioxide, with a solid substance, concrete, but the reaction of a gas, carbon dioxide, dissolved in a wet film, with the alkalis in solution, present in the concrete.

In this context, oxidation and corrosion are of fundamental importance. It is therefore important to note that corrosion is an electrochemical process that requires the simultaneous presence of an anode (depassivated steel), a cathode (defined by oxygen and water) and a wet electrolyte (concrete).

More general causes and causes can also be considered and investigated, such as the quality of the concrete, the quality and thickness of the concrete cover, the incidence and depth of carbonation, the possible presence of chlorides and stray currents.

POSSIBLE CONSEQUENCES: Spalling is consequent to a condition that has the value of extreme conservative criticality. In the absence of adequate and timely restoration measures, serious structural damage and static compromises that are difficult and expensive to remedy can result.

PREVENTION MEASURES: The most effective measures are the same as those generally adopted for the prevention of deterioration of the reinforced concrete conglomerate, contemplated in UNI EN 206-1: the design of a concrete of adequate quality for the exposure and service conditions, the provision of adequate thickness of the concrete cover, the careful implementation and compaction, the adoption of rigorous magistries of care and wet curing, the possible use, where necessary, of protective measures with covering or semi-covering paints impermeable to water and vapor permeable (like PROTECH WAC or PROTECH WAC-T). A further contribution can be provided by the addition of polypropylene fibers like READYMESH able to constitute an anti-cracking and inhibition of water motility.

RECLAMATION METHODS: The expulsion of the concrete cover is not a punctual phenomenon but the symptom of a deep degenerative condition. It follows the need for restoration interventions with a structural value, which require the removal of the degraded concrete (A), the dust removal, the saturation with water, the application of a re-alkaliser (B) like CONSILEX SAN, the preparation of the irons reinforcement up to the state of metallic shine, the application of a passivating micro cement mortar (C) like REPAR MONOSTEEL, the reconstruction of the removed and/or missing areas with suitable cement mortars (D) like REPAR TIX or REPAR TIX HG, any homogenizing smoothing like REPAR SM and protective finish with paints, covering or semi-covering correctly impermeable to water and permeable to vapor (E) like PROTECH WAC or PROTECH WAC-T.