Concrete works, structures and artefacts, whether they are beams, pillars, walls, balcony fronts, parapets, attics, etc., must necessarily be subject to maintenance through scheduled periodic interventions, because they are certainly and inevitably subject to degradation.

The causes of the deterioration of concrete can be many and of different types, however all addressed, in less or greater quantity and responsibility or with less or greater frequency, to jeopardize their functionality and overall durability.

The deterioration of concrete structures is a growing and inevitable phenomenon that makes necessary repair work, surface, cortical or deep, to protect the reinforcing bars exposed, rebuild the damaged parts, seal the cracks and protect structures from penetration of substances able to corrode iron armor.

The extent of the deterioration of concrete can be divided into four types

Concrete structure with light surface degradation, which involves a thin cortical thickness of concrete without ever compromising the reinforcement bars.

In the event that a cortical deterioration is found on a reinforced concrete product, as it is possible to occur on recently built works or if the structure has been built in a workmanlike manner, it will be possible to intervene with a surface protection.

The protection can be achieved with suitable paint, protective, water-repellent products (PROTECH WAC-T), in order to avoid the onset and progress of degradation or even more performing and conservative phenomena through a treatment with a corrosion inhibitor to impregnation that migrates towards the reinforcements (CONSILEX NO-RUST), attracted by them, to coat them internally with an anti-corrosive protection.

After impregnation, the surface can be further protected with a siloxane water-repellent treatment (CONSILEX NANOSIL T-1000) or always with a varnish, protective, water-repellent product (PROTECH WAC-T).

Concrete structure only degraded on the surface with the possible presence of exposed, corroded reinforcements (from 1 to 15 mm thick to be rebuilt).

Another circumstance is when the diagnostic tests have confirmed the absence of a deep deterioration on a reinforced concrete product and the presence of degradation is only limited to a cortical layer of small thickness (from 1 to 15 millimeters).

Situations of this type occur following the action of not particularly frequent freeze/thaw cycles, of weak chemical attack, of operating conditions that involve abrasion and erosion, of structural elements in which some reinforcement bars are placed too close to the surface.

In this case, the most correct intervention method consists in perfect cleaning with revitalization of the surfaces, followed by a reinforced leveling, the application of a layer of two-component mortar of limited thickness (REPAR SM BIC) with very high protective capacity and low modulus elastic, interposed with an alkali-resistant fiberglass mesh (ARMAGLASS 160) which creates, with a small thickness of application, a powerful super-adhesive protective barrier to the substrate. Further protection can subsequently be achieved with suitable paint, protective, water-repellent products (PROTECH WAC-T).

Moderately degraded concrete structure (from 15 to 50 mm of thickness to be rebuilt)..

A structure in which deterioration problems involve the removal and replacement of substantial thicknesses of concrete (from 1.5 to 5 centimeters) involving the reinforcement bars is classified as moderately degraded. The responsibility for degradation can be attributed to numerous and prolonged freeze/thaw cycles, advanced corrosion phenomena, expansive chemical reactions, erosion problems in hydraulic structures and also significant mechanical actions.

The need to remove substantial concrete thicknesses can also derive from the presence of layers of material contaminated by carbonates or chlorides.

In these cases, after the re-alkalinization of the substrates (CONSILEX SAN) and the passivation of the exposed reinforcing bars (REPAR MONOSTEEL or REPAR STEEL), the methods used for the restoration consist by: application of thixotropic structural mortars by spraying with suitable pumps (REPAR TIX HG SB) or by hand (REPAR TIX HG), with trowel, when working on vertical structural elements or on the intrados of horizontal elements; otherwise, when working on the extrados of horizontal elements, or on formwork applications, it will be convenient to use grouting structural mortars (GROUT 6).

Subsequently, the restored surfaces must be suitably smoothed to uniform them with the remaining, unrestored surfaces (REPAR SM or REPAR SM BIC).

The final protection will be subsequently realized with suitable varnishing, protective, water-repellent products (PROTECH WAC-T).

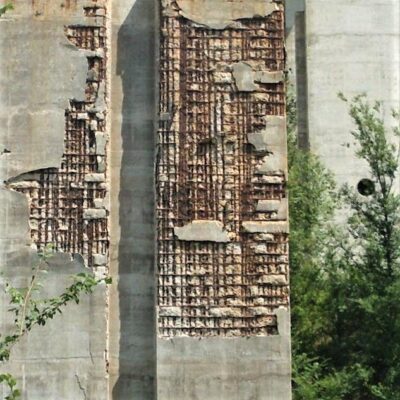

Deeply degraded concrete structure (from 50 to 100 mm and more than thicknesses to be rebuilt).

If the phenomena described for moderately degraded structures involve concrete thicknesses to be restored greater than 5 centimeters, specific high-performance products containing aggregate with a maximum diameter of around 6 millimeters (grouts) must be used. With increasing intervention thicknesses (over 10 cm) it will be advisable to integrate the above mentioned grout with siliceous gravel in granulometry 6-10 mm added in a proportion of 25% -30%.

With these intervention thicknesses, when working on the extrados of horizontal elements, after the re-alkalinization of the supports (CONSILEX SAN) and the passivation of the exposed reinforcement bars (REPAR MONOSTEEL or REPAR STEEL), the intervention methods that are used are almost exclusively those relating to the installation, in special formworks, of grouting cement mortars, anti-shrinkage (GROUT 6); with formworks when restoring vertical structural elements or intervening on the intrados of horizontal elements.