The checks that can be used to ascertain the health conditions of the concrete and therefore of the structure, before deciding with sufficient certainty the type of remediation to be carried out, are manifold.

Following the execution of these investigations, the conditions of the work will be determined, which usually will not present homogeneous degradation situations and therefore will require different methods of intervention according to the type, depth and extent of the problem.

Here are the most common diagnostic investigations.

OXIDATIVE EVIDENCE

The presence of halos and traces of rust on the surface, in correspondence with the bars, highlights an insufficient concrete cover and a corrosive process in progress.

CRACK EVIDENCE

Obviously the presence of cracking phenomena, more or less marked, visible to the naked eye indicate penetration of fluids into the concrete, progress of carbonation, very likely oxidative problems and durability of the reinforced concrete seriously compromised.

SPALLING PHENOMENA

Spalling, surface delamination and expulsion of the concrete cover are a clear symptom of a situation of corrosion of the reinforcement at an advanced stage.

EVIDENT STATE OF ARMOR

Conditions of any exposed reinforcement, are a clear indication of the severity of the deterioration. In these conditions, it is however useful to note the depth of corrosion and the minimum sections still in operation.

RESPONSE TO PERCUSSION

Carried out by percussion (with a hammer, for example) of the surfaces. A dull noise («like a vacuum sound») is an indication of possible detachments and delaminations.

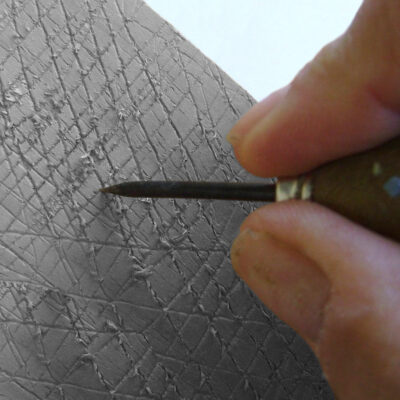

SUPERFICIAL HARDNESS

A porous concrete with a poorly crystallized cement matrix is generally endowed with poor surface hardness and a tendency to chalking. The incision test with a simple pointed tool can therefore give approximate indications about the state of health of the conglomerate.

CARBONATION DEPTH

The natural protection of the reinforcing bars inside the concrete matrix is guaranteed by the highly alkaline environment (pH 12.5-13.5) determined by the presence of calcium hydroxide Ca(OH)2 in the binding matrix.

However, over time, the atmospheric CO2 carbon dioxide, penetrating through the porosity of the concrete, reacts with the calcium hydroxide, giving rise to a chemical reaction which produces calcium carbonate CaCO3 and water H20. Decreasing the calcium hydroxide the cement matrix becomes less basic (pH 8.5-9) and when this phenomenon, called carbonation, reaches the level of the reinforcements, the natural protection of the same is lacking which, in the presence of humidity and oxygen, can oxidize to rust, triggering a disruptive expansion process on the concrete cover layer.

The measurement of the carbonation depth is determined by spraying on the surface of the cement conglomerate a 1% solution of phenolphthalein in ethyl alcohol. The reference standards are UNI 9944: 1992 – “Corrosion and protection of concrete reinforcement. Determination of the carbonation depth and penetration profile of chloride ions in concrete “and UNI EN 14630: 2007 -“Products and systems for the protection and repair of concrete structures – Test methods – Determination of the carbonation depth of a hardened concrete with the phenolphthalein method”.

The test is generally carried out on a concrete core immediately after extraction to avoid further attack by carbon dioxide), or directly on the structural element (removing, for example, the concrete cover of an edge).

Phenophthalein, which is normally transparent, turns red/purple in the presence of Ph>9. Areas that remain transparent therefore indicate the presence of areas where the reinforcement is not protected by the basic environment.

PRESENCE AND DEPTH OF BARS

The pacometric investigation is a non-destructive test for the identification of the reinforcement inside the concrete. This investigation uses the principle of measuring the absorption of the magnetic field, produced by the pachometer itself, which is highlighted by a digital system coupled to an acoustic system, for a more convenient and immediate detection of the metal elements.

By means of this magnetic survey it is possible to detect with good precision the position of reinforcing bars present in the reinforced concrete, their depth (concrete cover) and their diameter.

The pachometer is also extremely useful for:

- search for sub-surface pipes and conduits;

- search for hidden ties;

- locate reinforced structures (curbs, lintels, beams, pillars) immersed in the walls;

- localize attic floors, both in reinforced concrete and in brick and steel.

ESTIMATE OF COMPRESSION

The sclerometric investigation is a non-destructive test for the determination of the sclerometric rebound index of an area of hardened concrete using a steel hammer operated by a spring, known as a sclerometer or a Schmidt’s hammer.

This test is regulated by UNI EN 12504-2: 2012 “Test on hardened concrete in structures – Non-destructive tests – Determination of the sclerometric index”.

The test is based on the correspondence between the unitary compression breaking load and the surface hardness of the concrete, measured by the latter in terms of elastic energy released following the impact of a mobile mass with the surface of the element to be investigated.

The estimate of the mechanical resistance in place by means of a non-destructive sclerometric method must necessarily be calibrated and correlated with the mechanical resistance found following coring. The extracted carrots are subjected to a non-destructive investigation before they are broken.

The coupling of the sclerometric investigation with the ultrasonic investigation gives rise to the SonReb method. To use the SonReb method in estimating the mechanical strength of concrete, this combined method must always be calibrated and correlated with the mechanical strength found following coring. The validity of the SonReb method derives from the compensation of the inaccuracies of the two non-destructive methods used. In fact, it has been noted that the moisture content causes the sclerometric index to be underestimated and the speed to be overestimated, and that, as the age of the concrete increases, the sclerometric index increases while the ultrasonic speed decreases.

HOMOGENEITY AND RESISTANCE

The ultrasonic investigation is a non-destructive investigation which determines the speed of propagation of the pulses of the ultrasonic longitudinal waves in the hardened concrete.

This test method is regulated by UNI EN 12504-4: 2005 “Tests on concrete in structures – Part 4: Determination of the propagation speed of ultrasonic impulses” and is also described on the “Guidelines for the implementation of structural concrete and for the evaluation of the mechanical characteristics of the hardened concrete by means of non-destructive tests “ , of the Superior Council of Public Works – Central Technical Service.

Measurement of the propagation speed of the ultrasonic pulse can be used for the following determinations:

- homogeneity or inhomogeneity (presence of cracks, voids or honeycombs) in concrete;

- changes in the characteristics of concrete over time;

- dynamic modulus of elasticity

- on-site concrete resistance estimate

The coupling of the ultrasonic investigation with the sclerometric investigation gives rise to the SonReb method. To use the SonReb method in estimating the mechanical strength of concrete, this combined method must always be calibrated and correlated with the mechanical strength found following coring. The validity of the SonReb method derives from the compensation of the inaccuracies of the two non-destructive methods used. In fact, it has been noted that the moisture content causes the sclerometric index to be underestimated and the speed to be overestimated, and that, as the age of the concrete increases, the sclerometric index increases while the ultrasonic speed decreases.

COMPRESSION RESISTANCE

The pull-out test is a semi-destructive test since it produces limited damage to the concrete element (approximately diameter 55 mm, depth 25mm). This test determines the extraction force of a standardized, pre-embedded or post inserted metal insert in the concrete element to be tested. It allows to estimate the compressive strength of concrete and must always be calibrated and correlated with the mechanical strength found following coring.

This test is regulated by UNI EN 12504-3: 2005 “Tests on concrete in structures – Part 3: Determination of the extraction force”.

The pull-out, when used in the diagnosis of deterioration, estimates the correspondence between the force necessary to extract a standardized metal insert post inserted in the hardened concrete and the unitary compression breaking load of the concrete. The extraction force is representative of a complex state of stress, but the test is fast, has low prices, and the estimated compressive strength value of concrete is better than the correlations existing between compressive strength and rebound index (sclerometric test) or propagation speed of elastic waves (ultrasonic test).

This test can also be used to determine when to post-tension, when to remove shapes and props, when to stop the protection of the casts (especially in winter), or to carry out comparative tests.

CARROTAGE COMPRESSION TEST

It is a destructive test with which cylindrical samples of hardened concrete are taken by coring. The test is regulated by UNI EN 12504-1: 2002. The investigation allows to obtain cores of structural material which are carefully examined and then subjected to compression tests, according to standardized procedures, in order to evaluate, through appropriate corrective coefficients, the mechanical strength of the concrete on site.

The test is performed through a core drilling machine, an engine that rotates a core drill equipped with a water-cooled diamond crown, the diameter of which is chosen in relation to the maximum size of the aggregate present in the concrete matrix.

Preliminary to the coring operation is a pachometric investigation through which the reinforcing bars are detected in the area where the sampling is to be carried out, to be sure to exclude them from the coring path itself. The extracted carrotage are examined and, usually, subjected to the test to determine the depth of carbonation. They are then suitably protected and taken to the laboratory for the crushing test according to UNI EN 12390-3 (“Test on hardened concrete – Compressive strength of the specimens).

The coring must be performed in a very careful way: firstly because they cause damage to the structure, which is not totally remedied by filling the hole, even using high-performance structural mortars. Secondly, because the technique can be affected by important uncertainties, related to the coring operation itself (possible damage to the sample during operation and transport) or related to the variability of the compressive strength of the concrete along the same structural element (beam, pillar). For this reason, integrations and correlations with non-destructive (sclerometry, ultrasound) or semi-destructive (pull-out) investigations are useful, which can instead be extended to a large number of elements.